After doing some more sunrise yoga, I set about installing the electric lift pump. Like any project that makes me nervous (this includes doing anything with the engine), I first carefully laid out all my tools and all the components, then came up with a logical sequence of tasks.

This job would include cutting my existing fuel line (which was going to make me very nervous), inserting connectors and new fuel hose and clamps, mounting the pump and on/off switch on the wall of the engine compartment, then wiring it into the electrical system, ensuring it is protected by a fuse.

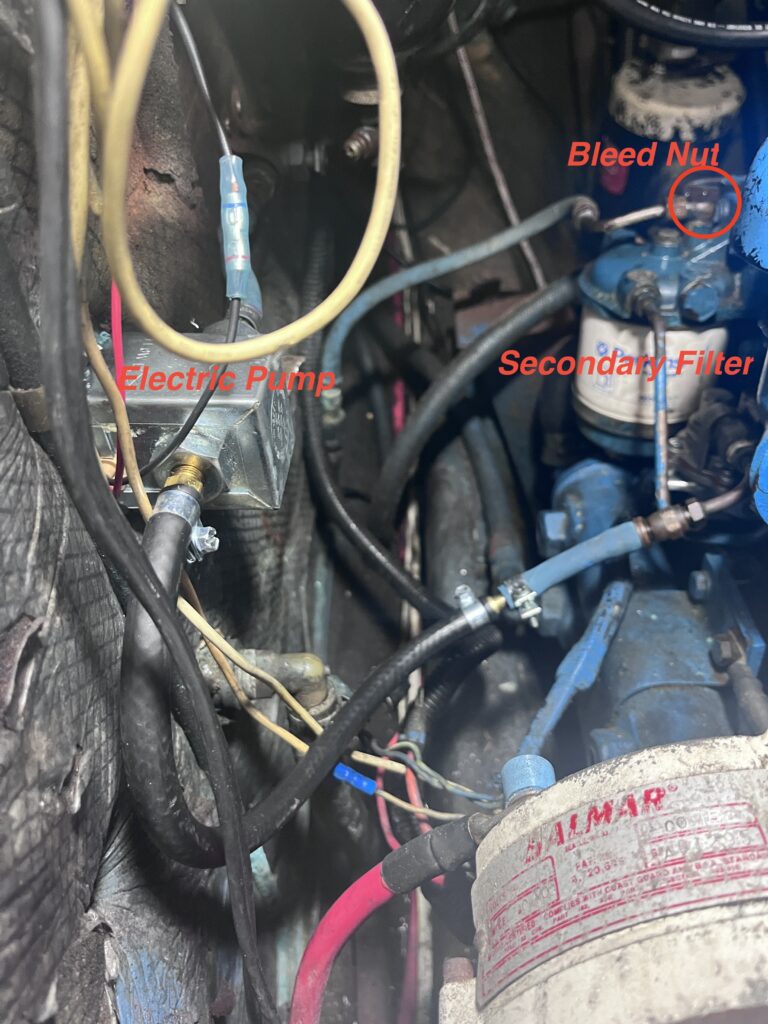

The plumbing/mounting part all went as well as could be expected. The electrical part was going to take a bit more work because I was going to have to completely empty both cockpit lockers in order to route the 16 gauge wires from the pump to the fuse panel in my port cockpit locker. Before going to all that trouble, however, I decided to hook up the pump to a 12-volt tool battery to make sure it worked. It did, and then, curiosity getting the better of me, I decided to see if it was going to work to bleed the engine, and so with the pump running off the battery, loosened up the nut on the first step of bleeding–the top of the secondary filter–and sure enough, after about 30 seconds a bunch of air bubbles came pouring out, and then pure fuel! Yea! It was going to work, so set to work wiring it into the system.

I had started the pump install at 7 am and finished around noon. I took a break for some lunch before starting the bleeding process, which I had never done before. I re-bled the secondary filter to make sure I had gotten all the air out of it. Then, after consulting some YouTube videos, I bled two points on the injector pump after which I tried to start the engine, but no luck.

More online researched about how to bleed the injectors themselves led me to realize that it was going to require turning the engine over! Since I didn’t have a remote start button and nobody to turn the key in the cockpit for me, this meant having to jump two terminals on the engine starter with a screwdriver. Yikes! Definitely outside my comfort zone!

Not knowing which two terminals to jump, I sent a photo of my starter to Steve Mitchum, Nicholay (who was just about in Key West at this point) and Lance. Steve Mitchum immediately called me up and was nice enough to video-chat me through the entire process. After I got over the initial scariness of the engine sparking and turning over right in my face, it wasn’t too bad. As I held the screwdriver against the two starter terminals, I used my other hand holding a wrench to crack open the injector inputs. I did get a bit of air out of one of them initially, but the engine still wouldn’t start.

-At this point, we were both confused because once you get to the point where there’s no air getting to the injectors-just fuel-the engine should start. Diesels are very simple machines. Steve had me double-check the fuel shutoff lever, but everything seemed to be where it was supposed to. Steve suggested I get some ether-type starting spray to give it a boost. Before I went back ashore, I decided to call Lance to see if he had any ideas. He went through the same stuff as Steve, and also couldn’t understand why it wouldn’t start. Then he asked, “Does your engine have glow plugs?” I said I thought so, but had never needed to use them to start the engine. He thought I should give them a shot for about 20 seconds and see what happens. So I did, and sure enough, she started right up!

I was so surprised and so happy! I never thought I’d be able to get it running again! Of course, it was with the help of many others with extensive experience with diesels (Lance, Steve, Nicholay, Compton) and the willingness to give me some of their time. I’m very grateful for them!

I continued to run the engine for about 20 minutes at 1500 rpm, then at idle for about five minutes, then put it in reverse and ran it up to 2300 rpm (under load from pulling against the anchor) and it ran fine through all of it. I shut it down and restarted it twice; no problem.

And yet. And yet, I was still a bit wary as we still don’t know what caused it to quit in the first place. I let Steve know that it started with the glow plugs, and we talked about why it might have quit. He thought I probably had water in the fuel and suggested I look into the tank for cloudiness or a boundary layer. I did, but all I could see was some black splotches on the bottom. He said that was water and I should pump it out. I confirmed online that the blotches were likely the bacteria that formed in the boundary layer between the water and the fuel, which indicated the presence of water (and which created threats in and of themselves to the engine), so I pulled out my oil change hand pump and attempted to remove them. But, none of them were loose. There didn’t seem to be any water, and even scrapping at the blotches with the firm hose didn’t do anything. Could they be tank corrosion? I removed about a 1/2 gallon of fuel from the bottom of the tank, but didn’t really see anything other than pure fuel. I decided to add two more jerry cans of diesel to the tank and some more fuel treatment (shock treatment dosage). Tomorrow I will motor about 6 hours to the next anchorage and will check the new primary filter then to see if it’s dirty. If so, I will attempt to have my fuel tank “polished” while at St. Augustine.

Even if we didn’t solve the problem, I am very proud and surprised that I was actually able to get it running again. The engine is now a bit less intimidating than it was a couple of days ago! 🙂

Ben has had to bypass the starter to start the engine. He keeps a piece of insulated wire handy to do this. Probably better than using a screwdriver.

Perhaps you should have someone polish the fuel when you get to your destination. Also put a clean out port in your fuel tank. There is a YouTube video from Calico Skies where Brian from Delos helps him put a fuel tank access port because Calico’s engine keeps quitting due to a dirty fuel tank.

Just my 2 cents.

Yes, good ideas, both. I’ve already been looking into fuel polishing–had it arranged up in Fernandina Beach, actually, before all this happened. Now the budget’s going to require me to wait a bit for that. It costs about $500, but is definitely good peace of mind.