Wednesday, 9/4/24

I woke up still pretty tired from my two days at the Anchorage from Hell. I probably should have started troubleshooting the electrical issue, but I wasn’t looking forward to it and knew that I needed to have a clear-thinking head to troubleshoot. I also knew from the weather forecast that I wouldn’t be able to leave Coinjock until Friday at the earliest, so decided to just take care off all the other little things that one catches up on when on shore and start the troubleshooting on Thursday. The weather was just about perfect, with partly-cloudy skies and temps in the mid-70’s.

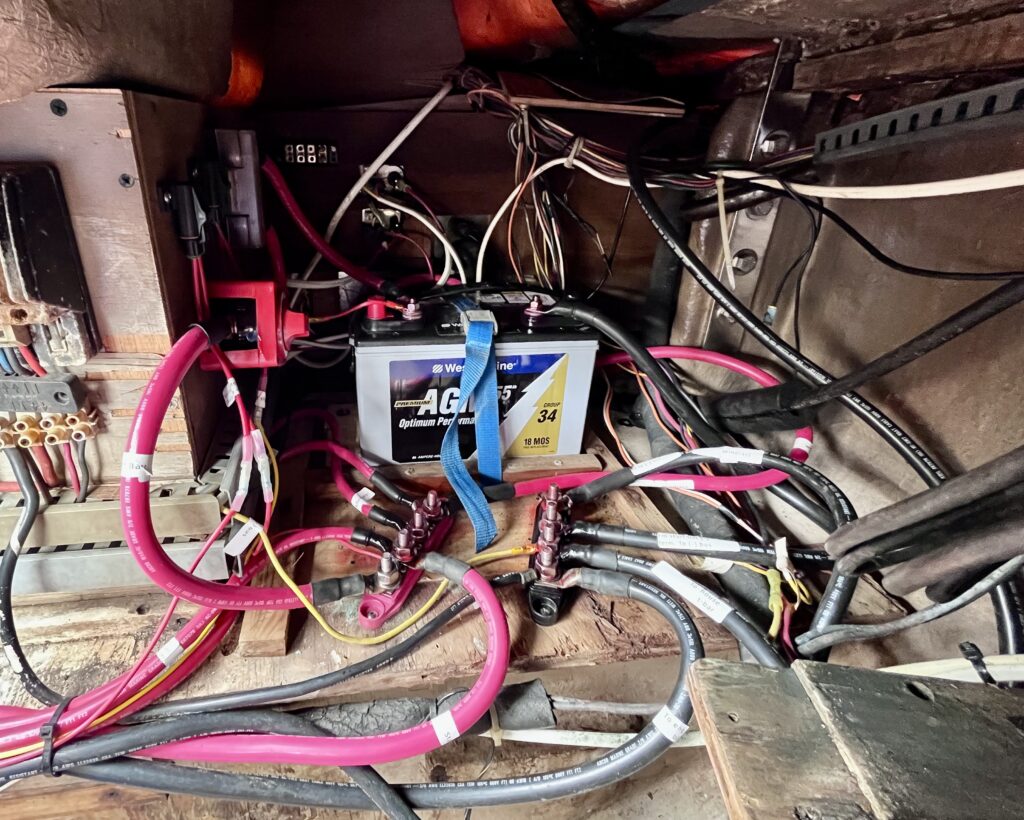

So, I topped off my freshwater tanks, flushed my deck wash system with freshwater, emptied my trash and composting toilet, did the dishes (which had stacked up while at anchor), did some yoga, meditation, and a little core workout. I did sort of start work on the electrical system: I emptied out both of my cockpit lockers (since I would be needing access to both of them to troubleshoot), stacking all the stuff on my forward deck so it would be out of the way. That didn’t take any clear thinking. I then treated myself to a nice steak dinner at the restaurant (and it was indeed very good) before getting to bed early.

**********************************

Thursday, 9/5/24

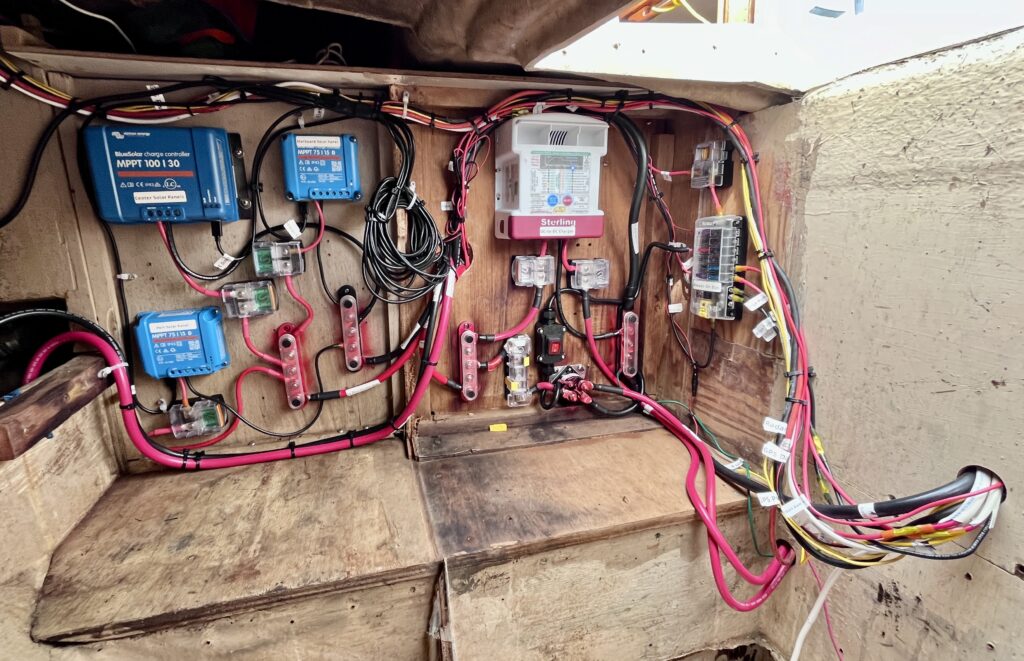

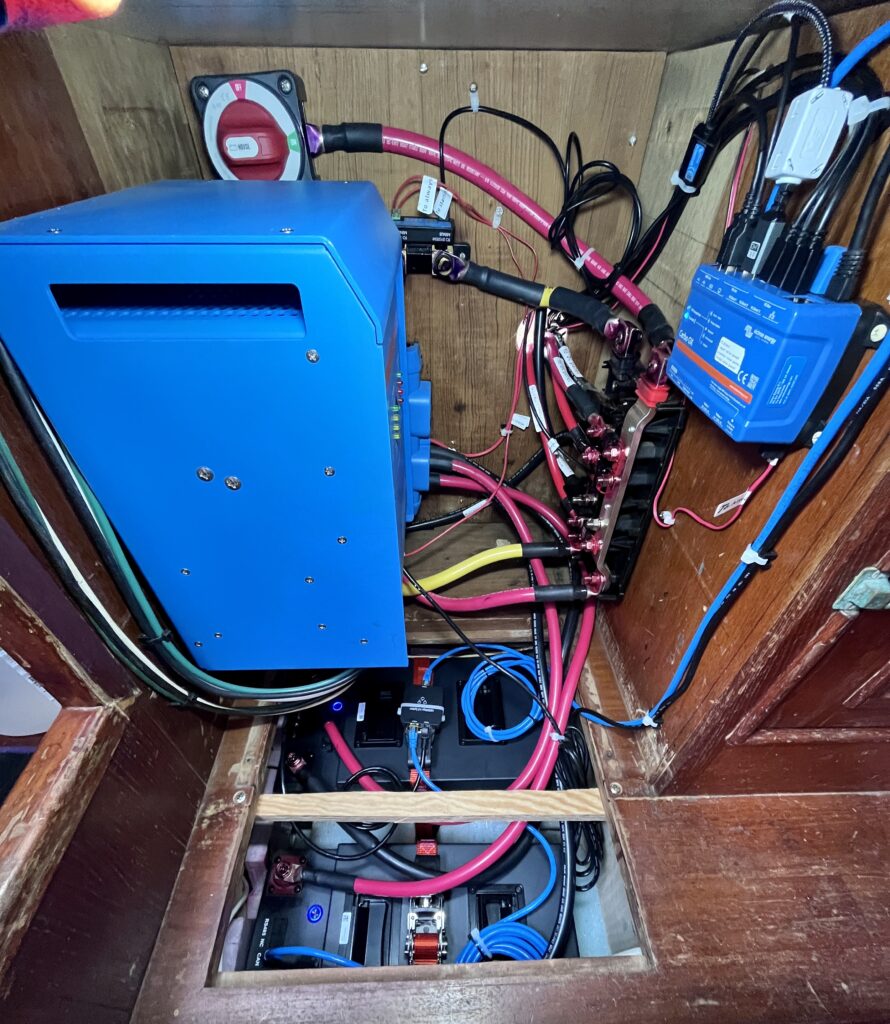

I started with the electrical system first thing in the morning. I decided to start with the starboard side, which is where the starting battery resides, and all the busses that connect it to the engine alternator, the windlass, and across the boat to the lithium side. I disconnected just about everything to check whether there was any corrosion or anything loose. There was neither; everything looked just like it did when I finished the project six months ago. So, I reconnected everything.

With that being done, I felt I should check whether I had fixed anything. I could do that either one of two ways. You see, there are two devices on the port side (in the port cockpit locker) that get power from the starting battery: the DC-to-DC charger and the Emergency Bypass (basically a car starter solenoid).

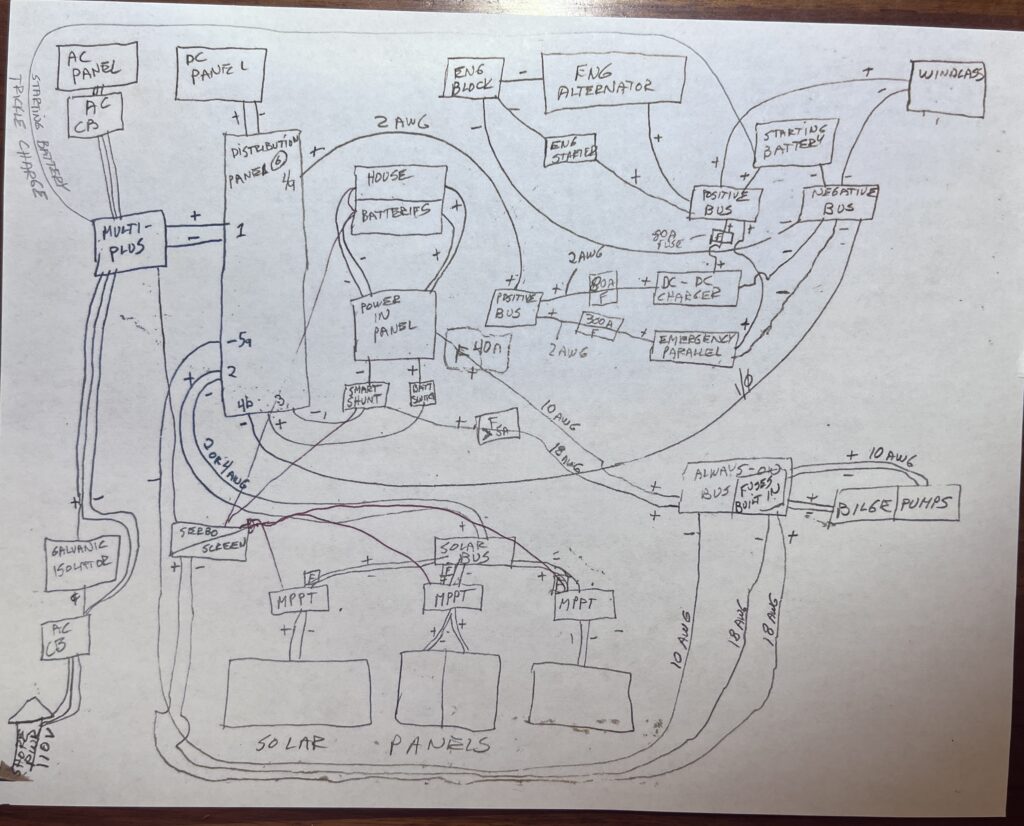

The DC-to-DC charger allows the engine alternator (via the starting battery) to charge the lithium (house) batteries. The Emergency Bypass allows me, by throwing a switch, to route power from the house batteries to either the engine starter or the windlass in case the starting battery goes dead. These two devices’ positive wires merge at a bus bar then go to the main distribution bus (which eventually goes to the lithium batteries). Here is a diagram of my electrical system which will make it all clear. 😉

After the first day of troubleshooting (at anchor), Nicholay and I discovered that the Emergency Bypass wasn’t working. I.e., if we turned the starting battery off and turned the Emergency Bypass on, the windlass would not work. Since both the DC-to-DC charger and the Emergency Bypass were suddenly not working, we figured that the trouble must be in their common wiring; there must be a loose connection somewhere. So those were the connections I was targeting. So, once I had checked all the connections on the starting battery side, I decided to check if I had fixed things by trying to use the Emergency Bypass and the windlass (vice trying to start the engine using lithium). No joy. The windlass just clicked again, but wouldn’t move. Okay, time to move on to other parts of the system.

Next, I decided to tackle the two main engine electrical connections: the positive coming off the alternator and the negative going to the engine block. It took me about an hour to clean both of those up and reconnect them. (There nothing particularly noticeable about them, either.) Then I tested the Emergency Bypass/windlass again. Same thing. (Dang! I was really hoping this would be where the source of the problem was because these were the only connections that I hadn’t redone during the lithium project.)

Okay, on to the port side of the system, which had the connections to the DC-to-DC charger and the Emergency Bypass. As I began taking these apart and reconnecting them (they also all looked brand new), I noticed that when I’d turn the Emergency Bypass on, the solenoid didn’t click like I thought I remembered it doing when I installed it. If the problem were the common wiring between that and the DC-to-DC charger, the solenoid still should have open and shut when I threw the switch. I decided to check its 10 amp fuse and sure enough, it was blown! I found a replacement, but as soon as I put it in, it blew! Aha! The solenoid was bad! It was shorted out somehow. That would explain why the windlass wouldn’t work–the malfunctioning solenoid wouldn’t let any power go through.

But that didn’t have anything to do with the DC-to-DC charger! So, that whole logic–that it must be the common wiring between the two–turned out to be just a red herring! So, I might have actually fixed the DC-to-DC problem with the troubleshooting I had already done. But, checking it by trying to use the windlass wouldn’t work; I would have to start the engine to see if it would charge the lithium batteries. So, I started up the engine, waited for awhile….and….nothing. Still no go. 🙁

One last set of connections to try, and that was on the opposite end of the common wire between the DC-to-DC charger and the Emergency Bypass–where the wire from the bus bar went behind the bulkhead and connected to the main distribution bus (and its negative counterpart, too). So, into the cabin and the main electrical compartment. So, I spent another hour disconnecting those wires (and the associated fuse), but they also looked brand new and were solid connections. I tried the engine one last time, but still no good.

So now we were back to it being a bad DC-to-DC charger! I called Nicholay to get his input. He couldn’t think of anything else to try and agreed that it must be a bad charger.

So, the next step was to call the company (Sterling Power), but it was British based. I was not looking forward to the expense of calling England on my cell phone. And, unfortunately, their website said their email server wasn’t working right and the only way to contact them was via phone. I tried calling them numerous times, using different numeral prefixes, but always got Verizon error messages. So I called up Verizon to figure out how to do it, and it turns out that I can’t call internationally with my current plan! It was then that I noticed a small link at the very bottom of Sterling’s main website which said “SterlingPower U.S.” I clicked that, it called up a U.S.-based website, and a U.S. phone number, which I immediately called.

A guy named Jeff immediately picked up, and I briefly described what was going on. (I know, hard to believe I could be brief, right!?) Lol He agreed that it sounded like a bad charger and said he’d send a replacement out to me right away. I’d just have to pay shipping. Very easy! So, that’s on its way, as is a replacement solenoid from Amazon. (I think the solenoid might have gone bad because its terminal screws are exposed to stuff that I store in the anchor locker (and all the other electrical connections have covers). It’s possible that something rested up against it and shorted it out. I will have to come up with some kind of solution for that when I install its replacement.

So, all this troubleshooting took me most of the day, and all of it was for moot because the problem wasn’t in any of the connections after all. But, I was glad at least to have finally (hopefully) found the culprits, and replacing them should take just a few hours. Jon and Trish were kind enough to let me ship both items (and some other things from Amazon that I need) to their home. Unfortunately, today is Thursday, and the charger won’t get shipped out of Sterling U.S. in Maine until Monday at the earliest, which means probably a Wednesday next week arrival. That means I need a place to hang out for a week (because I’m no going to sit around here in Coinjock at$150/day!)

So, after looking at the options, it seemed like heading to Elizabeth City would be the best. Yes, it would mean spending a day going south instead of north1, but it was supposed to be a very cruiser-friendly town, and even had some free docks right downtown. It also had a small yacht club that I supposedly had reciprocity with that I might be able to stay at for a day or two. And, the best thing was that with the northeasterly winds, I might actually be able to sail half of the journey over there tomorrow. Oh, and Elizabeth City had a bicycle shop that might be able to repair my frozen freewheeling unit, and being there until at least Wednesday meant that they’d probably have time to fix it. I’d be killing a few birds with one stone.

- The need to meet with Nicole in Norfolk on September 7th had disappeared. She had come down with a nasty case of the shingles and had to cancel. For the first time since leaving Florida, I truly had no time deadlines and no place to be. Complete freedom! So, why not Elizabeth City!? ↩︎