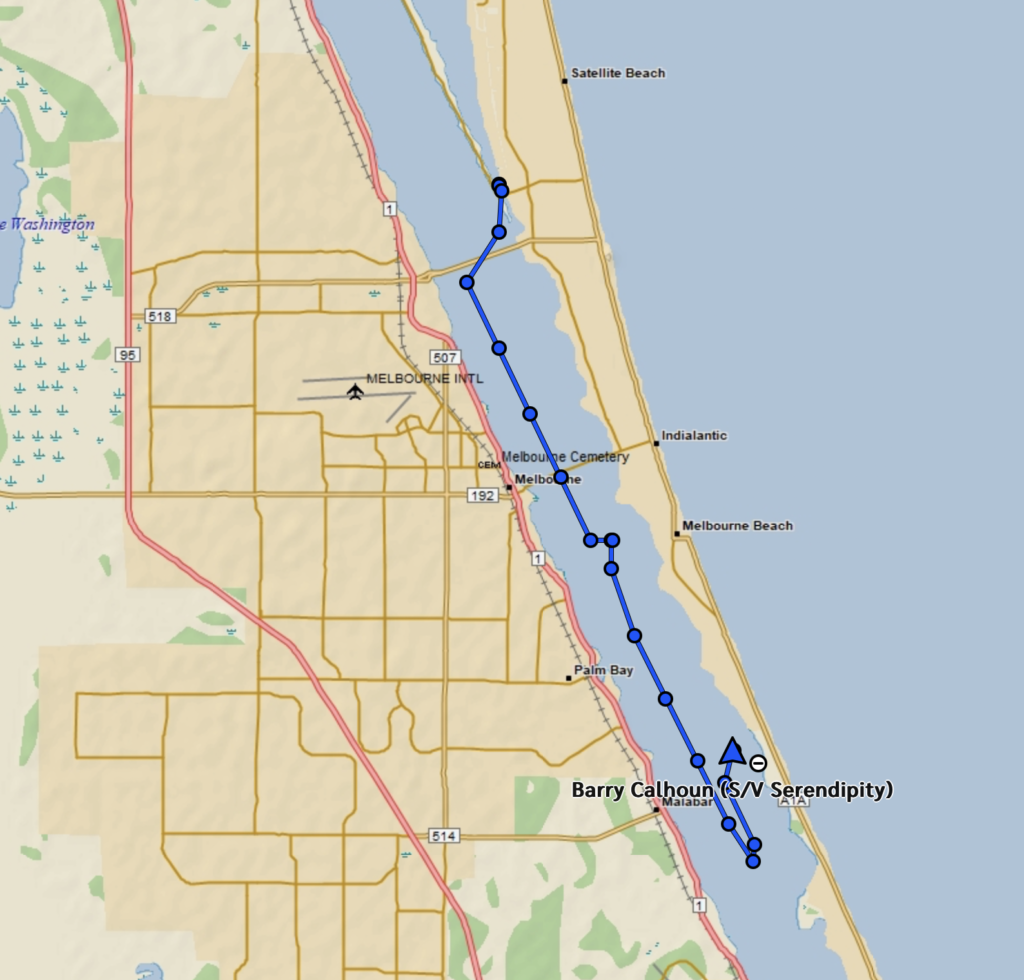

Banana River anchorage to Coconut Point anchorage. Distance: 13 nm/Time: 5 hrs

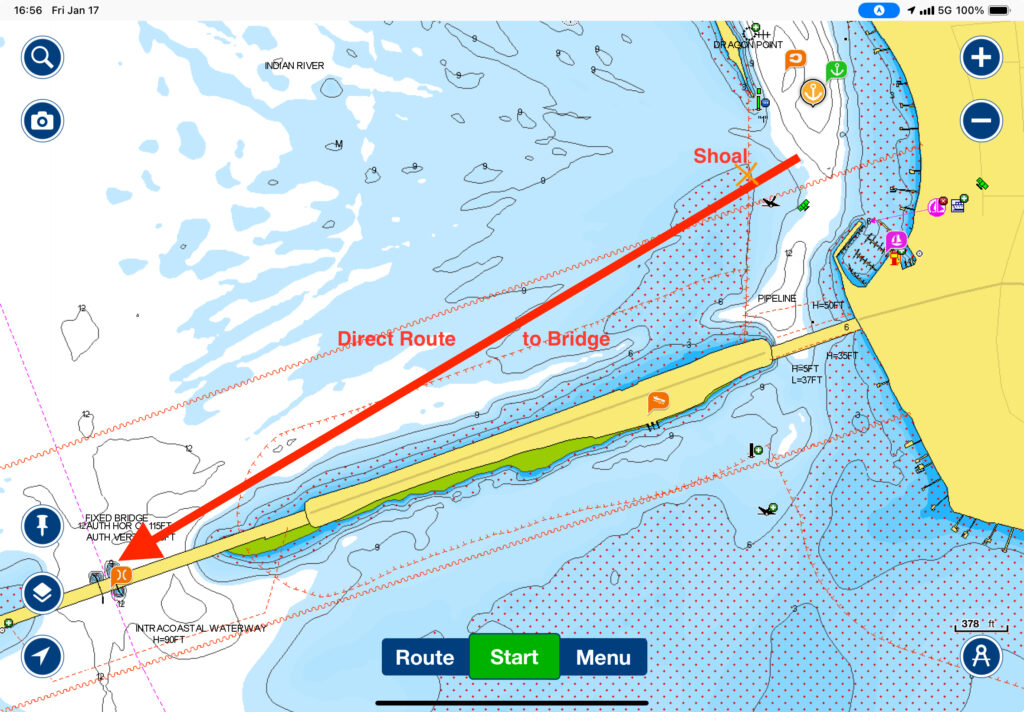

I weighed anchor in the peaceful Banana River anchorage at 7:50 and immediately called the Mathers Bridge tender for an opening. After passing out of the river, I set a course directly for the Eau Gallie Causeway Bridge just to the south, and five minutes later just about went aground! I was distracted by the views exiting the river and didn’t look carefully enough at the chart.

If it hadn’t been for my depth sounder alarm going off at 7′, I would have just plowed straight ahead into the shallows and run aground. As it was, even with an immediate turn north, I still saw under 6′ on the depth sounder before I ended back up in deep water. Yet one more time that my depth sounder’s alarm has saved my inattentive bacon!

My plan was to make it to Vero Beach about 33 miles away. I had heard a lot of good things about Vero–at least from a cruiser’s perspective–so thought it would be worth a look. Evidently, it is not only a staging ground for cruisers waiting to cross to the Bahamas, but also a place where many cruisers just spend the entire winter. There is a small city marina there with two large mooring fields which get so crowded in season that the city requires boats to raft up to three to a mooring ball! You certainly get to know your neighbors well when your boats are tied together for months.

I didn’t plan to raft up, since I wasn’t going to stay long enough to make that process worthwhile, so hoped I’d be able to find a spot at one of the small anchorages nearby.

Alas, in the event I wasn’t even able to make it halfway there before breaking down!

I noticed fairly quickly as I turned south and the engine came up to temperature, that it was reading a bit high. It was showing 190 degrees at my cruise RPM of 2000 when it had been consistently 180 for months. This bothered me–something was wrong. I could just keep going and keep my eye on the temperature. After all, for a long time I had run the engine at 210 degrees before I had it on the hard and was able to clean the heat exchanger. But, for this temperature rise, even though relatively minor, to happen so suddenly was suspicious. At this point, it had been two and a half hours since I had departed, and it seemed to me that the temperature was continuing–very gradually–to increase even above 190.

The problem was that I was approaching a section of the ICW that was very narrow; there was no “shoulder” to turn into if I needed to get out of the channel and drop the anchor. And, it would be this way for many miles. I didn’t want the engine to get worse but then have no place to go. So I made the decision to turn around, go back to a wide open area I had just passed, drop the hook, and do some Internet research about possible causes of my overheating.

Before shutting down the engine after anchoring, I checked it visually. Everything looked normal. The only thing that I had done that might have affected the engine’s cooling system (besides rebuild the raw water pump a month prior), was that I had changed the zinc in the heat exchanger before leaving Titusville two days prior. During that process, I had been unable to pull a chunk of the old zinc. Some quick Internet research revealed that this could cause the engine to run a bit higher for a while due to restricted water flow (until the zinc piece fully dissolved).

Satisfied that this was the issue, and resigned to the fact that I’d likely see 190 degrees for a few days, I cranked back up, weighed anchor, and once again headed south, towards the narrow part of the ICW. But this time, the temperature rose even higher–to 200 degrees–in a rather short period of time. So, I decided to turn around again and check out the zinc I had put in. I also decided to let the engine get cool enough to check the coolant level. So back I went to the anchorage and dropped the hook again.

After 30 minutes, I pulled the zinc and could sort of feel the remnant of the previous zinc inside. Thinking it might be blocking flow, I decided to not re-install the new zinc, but just replace it with the old zinc’s screw head. This was the exact state it had been in before I had changed it, afterall, and the temperature had been fine then, so I decided to see what that would do. (The coolant level was fine, as was the strainer.)

I had noticed on the way back to the anchorage that if I lowered the RPM to 1500 or so, the engine would cool back down to 180 or less, so I reasoned that even if what I had done hadn’t solved the problem, I could at least cruise along at 4 knots if necessary. Vero Beach, still 20 miles south, seemed like the best bet to find a diesel mechanic if needed. But, at four knots, Vero was too far away for today, so I picked an anchorage about 2 hours away at four knots, cranked up, and headed for it.

But, this time, before I could even get back in the ICW, it was obvious that something was very wrong. The exhaust was making unusual noises, and the temperature was rising quickly, past 195, up to 210. I slowed way down, quickly did a 180 to try to get back to the anchorage, and then that I realized that no water was coming out of the engine exhaust! Yet, I still had 1/2 mile to get to where I could anchor, so I throttled back to idle, but the temperature was still rising, and then the hot temp alarm came on at about 230 degrees. I decided I had to shut the engine down and try to sail into the anchorage.

So, as the boat was coasting to a stop and threatening to drift out the ICW into the shallows, I quickly unfurled the Genoa to capture what little wind there was (about 5 knots). It thankfully gave me some steerage at 1.5 knots, and we slowly made our way back to the spot where we had anchored previously. I now suspected the impeller/raw water pump which I recently rebuilt had come apart inside. If there was no water coming out of the exhaust, that was the most likely culprit. I probably didn’t install it correctly when rebuilding it (inside of which is the impeller).

At this point I was very worried, even a bit panicked. Here was another major engine issue, I was in the middle of nowhere in the ICW, I would have to find a marina, then a mechanic, but I needed to get there to be able to do that, and how could I get there if my engine was broken?

It took me awhile to think past the anxiety and realized what my situation actually was. For the longest time since launching back in May, my subconscious always had me thinking that Tampa was “home”, and that I was just making some forays out to cruise, but would keep coming back. But the reality was that I’m not really planning to go back to Tampa. As much as I love the Davis Island Yacht Club and all the people associated with it, I don’t have any intention of going back there. It isn’t along the way to any cruising grounds, it is a rather an inconvenient place to live aboard (from a logistics sense–one really needs a car there.) Only one of my sons out of three even lives in Florida anymore. So, it is not in my plans.

Yet, my subconscious still thought of it as “home,” and when something was going wrong, I needed to get home. Strange. When I realized that there was no “there” there–that there was no place I needed to get to, it gave me some peace. I was on my home; there was no place I had to get to. I could fix my problem somewhere locally, that even as I sat there, I could live on the boat for at least a month at anchor. I realized that if I needed a mechanic, I would just have to find one somewhere in the vicinity, and if his appointments were a month out, I would just wait. And, I had towing insurance that would get me where I needed to go. I had no place I had to get to, no deadline.

So, with this unexpected but welcome sense of calm, I set about troubleshooting the engine. When it had cooled enough, I pulled the cover off the raw water pump expecting to see only pieces of the impeller, but to my (pleasant) surprise, it looked fine. Hmmm. Then noticed that the bilge was almost completely full!1 That meant that there was a leak somewhere in the cooling system. Sure enough, I found it in the first place I looked; a small 4″ hose coming off the raw water pump had about a 2″ split in it! That was why the impeller was still intact; had the leak been on the other side of the pump, the impeller would have been running dry and would have disintegrated, its pieces likely jamming up the heat exchanger, and generating a lot of work to fix it. But, as it was, as long as I had a 4″ section of appropriate hose aboard, I should be able to affect a repair!

Had I checked the engine at full rpm instead of at idle, I would likely have seen water spraying out of the hose. But, my autopilot is so sloppy that I hadn’t wanted the risk of taking the time below to remove all the ladders and covers required to view the engine while motoring along the ICW. The rip had probably started small and increased throughout the day, which explained what I had been seeing in the temperatures.

Luckily I did have some spare hose, and with the help of a heat gun, some dish soap, and a lot of muscle, I was able to replace the section in a couple of hours. Then I cranked the engine and watched the hose. No leaks! So far, so good. But, I wanted to put a load on the engine and bring it up to temperature before I re-entered the ICW the next day, and so weighed anchor, headed north, and motored 20 minutes at 2100 rpm to another anchorage that was in the same wide section I was in but better protected from the NE winds which were forecast overnight. The engine temperature ran just under 180 degrees the entire time. Hurray! After anchoring for the fourth time that day around 3 pm, I ensured the engine still had no leaks, then put the new zinc back in the heat exchanger since that hadn’t been the problem.

Then I relaxed the rest of the day, feeling pretty satisfied, both that I was able to repair the engine myself, and that I had a new sense of my cruising status: That I was home (on my boat), that I didn’t have to be or go anyplace that I didn’t want to and could take my time now.

- I purposely had the float switch to the bilge pump turned off because I was soaking the bilge with cleaner for a few days. ↩︎

Good https://is.gd/tpjNyL