Buck Island South Anchorage

Woke up on Saturday to about the same winds as Friday. Northeast at 13 knots gusting to 20 or so. This kept consistent for the next two days. I did notice evidence of the infamous midges in the cockpit, however. Somehow during the night they had visited the boat, hung out around the cockpit, and left the little blue blotches for which they are known (midge poop?). I will have to clean all that the next time I had access to freshwater.

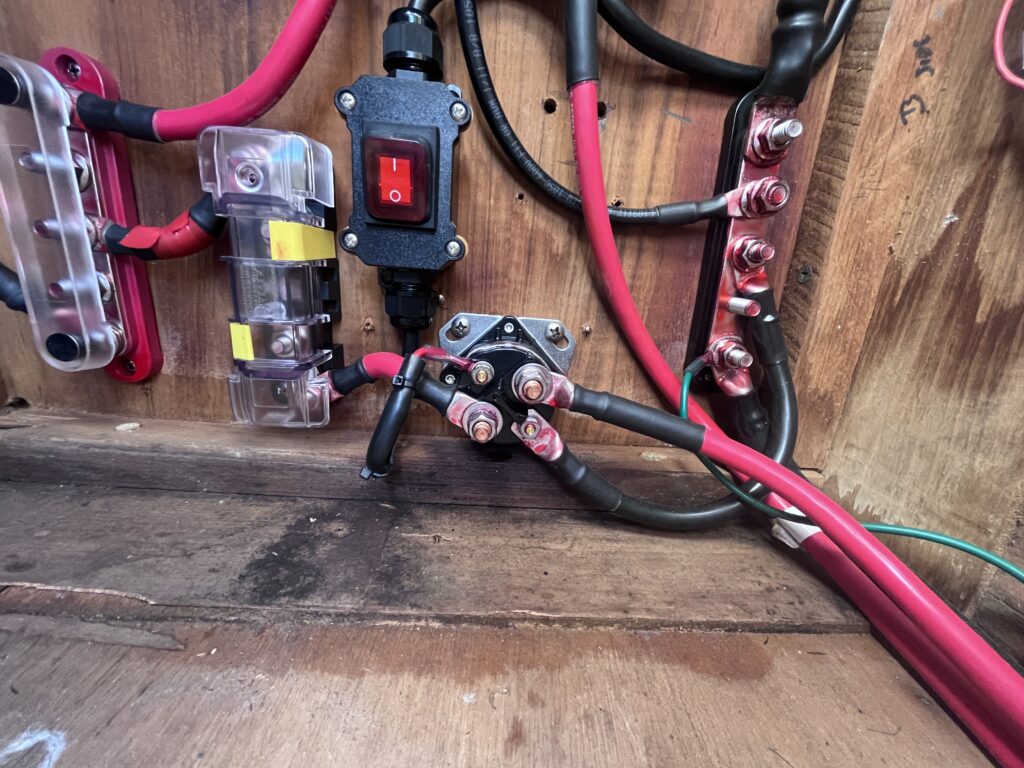

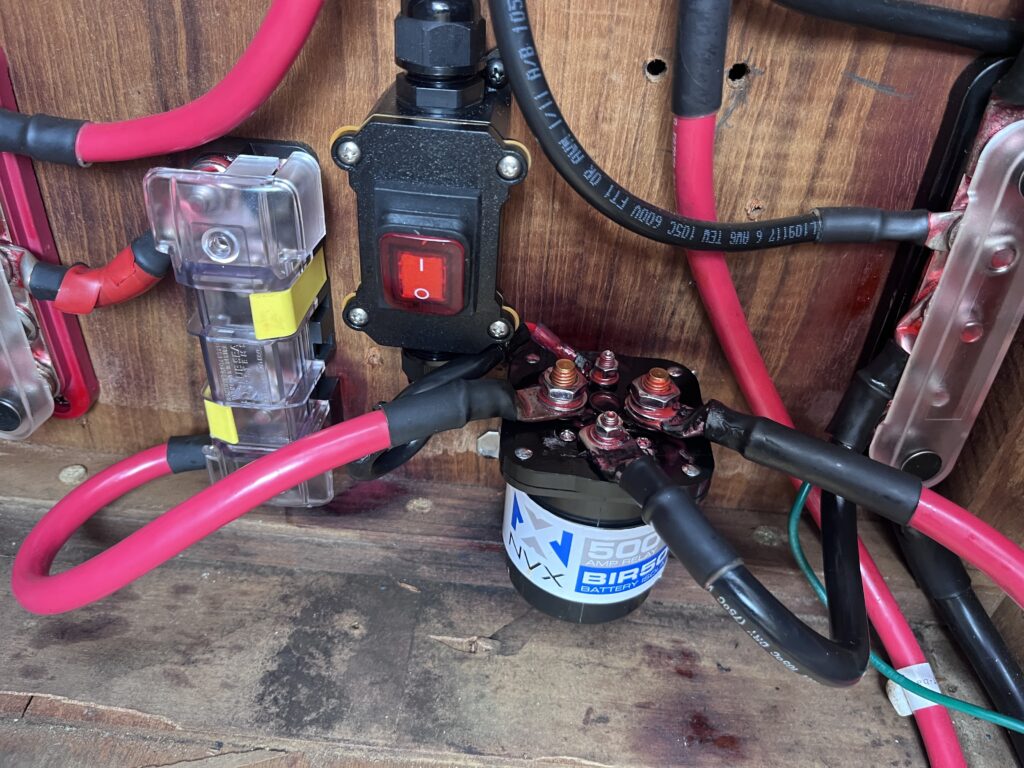

I had a nice omelette for breakfast, then started on my project for the day.And that was was to install the new, continuous power Emergency Bypass solenoid, which I accomplished successfully in the afternoon. It is much heavier and more substantial than the intermittent power versions I had before.

Anticipating that I would have to cut some new wire (which would be 2 gauge, i.e., thick!) to connect the new solenoid (because it was not the same size or shape as the previous version), on Wednesday I had biked to Harbor Freight to purchase some hydraulic crimpers1 for the job. I knew I had plenty of spare wire from the lithium project, but had always borrowed hydraulic crimpers from Sean Motta or Nicholay. So, after putting the new set on the boat, I figured I was all set.

But, what I had forgotten was wire cutters for such thick wires (which I had also borrowed). So, I had no good way to cut through the 1/2″ thick 2 gauge spare wire that I would need to wire-in the new solenoid. Luckily, I found a spare piece of 2 AWG that already had two lugs on it. It was a bit bigger than it needed to be (for aesthetic purposes) and one of the lug holes was too small, but the former didn’t matter, and I just drilled out the latter, so had the entire thing installed in about two hours.

I also took the time to install my new fire blankets. These were something that I had wanted to get ever since observing Safety at Sea day at DIYC a few months ago. They are basically fiberglass blankets that can be thrown on a fire or draped around oneself to run through a fire. I was reminded of their benefit during my Coast Guard Auxiliary safety inspection in Oriental and found a cheap pair on Amazon, so had them shipped to Jon’s with my solenoid. I installed one forward and one aft (near the galley).

The rest of the day I spent blogging, doing yoga and a workout on deck (exciting in the 20 knot gusts)! I still had the transmission shifting issue to troubleshoot, but since I planned to be at anchor through Tuesday, I felt I had plenty of time and so relaxed the rest of the day. The only other boat I saw was a crabber checking his pots.

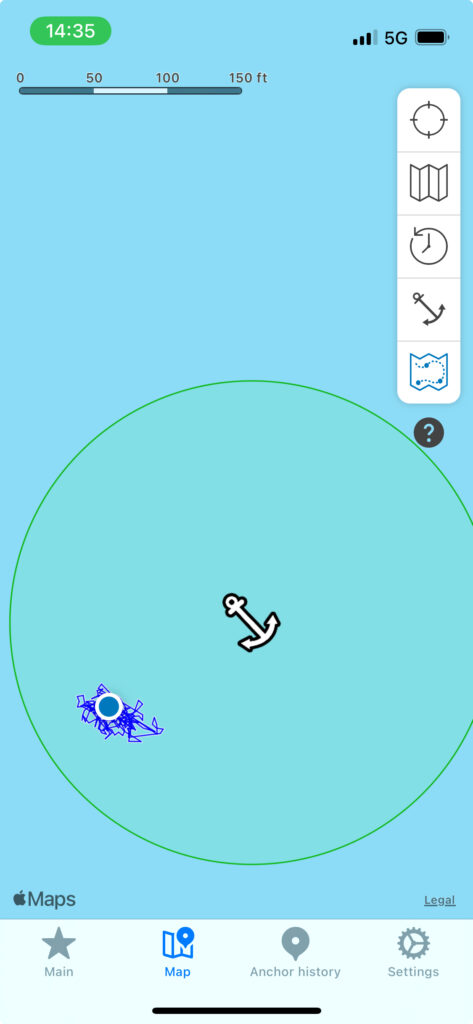

Sunday, the winds built, with the gusts getting up to 25+ knots. The sun was also out intermittently and the temperature a bit warmer. Despite the strong winds, thankfully the anchor was holding well.

This was going to be transmission day: trying to determine why it didn’t seem to go into forward gear as…cleanly as it did in reverse. It could be that the linkage from the cockpit lever was misadjusted, or that it needed new fluid. These things I could sort of check. Other than those, I hoped it didn’t mean that my transmission was going bad.

I checked out the linkage first, and couldn’t really find anything wrong with it after consulting the manual. Yes, reverse moved the lever on the transmission a bit more, but forward was within spec. In fact, when running the helm lever through forward, neutral, and reverse with the engine off, it felt just fine; forward felt the same way as reverse. I decided not to mess with the linkage after reading on the web forums how difficult it can sometimes be to get the adjustments right. For right now, at least, it would be a case of “if it ain’t broke…”

So, I decided to change the fluid, because old or not enough fluid can cause problems. I had changed the fluid about 300 hours ago, not long after I bought the boat. It was nasty then, and smelled horrible! So, it wasn’t due to be changed for another 100 hours, but it certainly wouldn’t hurt to change it early, and it would be another troubleshooting step. The existing fluid still looked very good, pink and with really no odor. But, I changed it out anyway; might as well reset the clock since I had most of the work done just getting the fill plug/dipstick removed. So, that is done, we’ll find out tomorrow if there is any difference.

And speaking of tomorrow, the forecast has changed for the worst. A low pressure system off the Carolinas/Georgia coast which had a small chance of development is now going to be something to contend with. The forecast now is calling for possible Gale or near-Gale force winds late Monday into Tuesday (i.e., winds 20-25 knots with gusts up to 35 knots). That in itself isn’t horrible as I am in a pretty good anchorage for north to east winds, but Tuesday they are supposed to veer to southeast, which would give me no protection and a large fetch. I’d be doing Currituck Sound all over again, but probably worse. I didn’t want to deal with that again.

So, I’m going to be pulling the hook tomorrow morning and heading to Coinjock marina yet once again for two days. 🙁 It’s not that I don’t like the place. It’s very nice and peaceful. It’s just that it’s another two days of marina costs that are not in my budget.

All of these issues over the past two weeks have been caused by there being a dearth of anchorages between here and Norfolk. Had there been just one appropriate anchorage between here and there, I would have been up in the Chesapeake about two weeks ago. But, I have to go 50 miles, and through four timed drawbridges and one timed lock–all on the same day. It will be a challenge to do it all in the daylight, so the conditions have to be just right. And there’s always been the same thing preventing it: the strong northeast winds! It isn’t that they are dangerous–even with the small craft advisories I never saw seas over 3 feet in the forecast–its just that the waves and wind off the nose would slow the boat down so much going across the 10-mile-long Currituck Sound that I wouldn’t be able to make 50 miles in a single day.

The good news is that starting Wednesday, the winds are supposed to calm down to 5-10 knots from the south for a couple of days. That should allow me by the end of Thursday to get all the way to an anchorage up in Mobjack Bay in the Chesapeake which I’ve been targeting for a month now. Fingers crossed!

I was going to need to hit up a marina for a night, anyway, to refill my freshwater, wash down the midge poop, do some laundry, empty the trash, and get some gas, so I was budgeting one night. But, it was going to be at a marina up near Norfolk, so I’d have full tanks once I entered the Chesapeake. Ah, well. it’s not a big deal. First World problems again.

So, this evening I will reconfigure my boat again for docking so that in the morning I can weigh anchor shortly after first light and get into Coinjock shortly after they open at 8:00. (I want to make the most out of my marina time, and it’s going to start raining pretty heavily tomorrow afternoon through Tuesday, so I want to get my outdoor stuff done as soon as possible tomorrow.)

- For wires that thick, hydraulic crimpers are really the only way to securely attach a lug to the wire. And after that, heat shrink needs to be added to encapsulate the joining of the two. ↩︎